Humanity returns to the Moon

– this time to stay.

As Lunar missions expand, reliable infrastructure for astronaut safety and research is crucial. Transporting materials from Earth remains extremely costly (600,000–1,200,000€ per kilogram). This makes In-Situ Resource Utilisation (ISRU) – use of local materials – essential for a sustainable presence on the Moon.

Video by NASA/Goddard Space Flight Center

2023-2024

Miniaturized MoonFibre spinning

Successful conclusion of the ESA BIC project, demonstrating that a miniaturized fibre spinning machine can produce fibres from Lunar regolith.

2025–2027

ESA Accelerator Phase 2

→ Abstract “MoonFibre: Enabling Lunar Autonomy Through In-Situ Fibre Manufacturing” to be presented at the Space Resources Conference (Texas A&M, April 2026).

2027

Launch-ready demonstrator

Develop an autonomous fibre manufacturing system on the Moon (ESA BSGN), using local regolith and energy to produce MoonFibres.

2032

First spinning on the Moon

Planned demonstration of fibre production directly on the lunar surface to validate the MoonFibre technology in real conditions.

2023-2024

Miniaturized MoonFibre spinning

Successful conclusion of the ESA BIC project, demonstrating that a miniaturized fibre spinning machine can produce fibres from Lunar regolith.

2025–2027

ESA Accelerator Phase 2

→ Abstract “MoonFibre: Enabling Lunar Autonomy Through In-Situ Fibre Manufacturing” to be presented at the Space Resources Conference (Texas A&M, April 2026).

2027

Launch-ready demonstrator

Develop an autonomous fibre manufacturing system on the Moon (ESA BSGN), using local regolith and energy to produce MoonFibres.

2032

First spinning on the Moon

Planned demonstration of fibre production directly on the lunar surface to validate the MoonFibre technology in real conditions.

2023-2024

Miniaturized MoonFibre spinning

Successful conclusion of the ESA BIC project, demonstrating that a miniaturized fibre spinning machine can produce fibres from Lunar regolith.

2025–2027

ESA Accelerator Phase 2

→ Abstract “MoonFibre: Enabling Lunar Autonomy Through In-Situ Fibre Manufacturing” to be presented at the Space Resources Conference (Texas A&M, April 2026).

2027

Launch-ready demonstrator

Develop an autonomous fibre manufacturing system on the Moon (ESA BSGN), using local regolith and energy to produce MoonFibres.

2032

First spinning on the Moon

Planned demonstration of fibre production directly on the lunar surface to validate the MoonFibre technology in real conditions.

MoonFibre

MoonFibre is a pioneering project developed together with the European Space Agency (ESA) to produce fibres directly from Lunar regolith – the dust and rock covering the Moon’s surface. MoonFibre will be an essential piece of the materials mix on the Moon:

- 26× higher strength compared to bricks made from Lunar rock or 3D-printed regolith

- 100× higher surface area than bricks, ideal for filtration and dust prevention

- Potential to reduce dust by up to 100% in landing and construction zones

MoonFibre paves the way for self-sustaining Lunar infrastructure by transforming local regolith into strong, versatile fibres. MoonFibre serves as a reinforcing construction material, forms dust control mats, and provides a substrate for hydroponic plant growth systems. By enabling local production, MoonFibre reduces launch costs and supports a sustainable human presence on the Moon.

Landing pads and roads

Dust is a central challenge on the Moon due to the absence of humidity and the space environment grinding down the particles of the surface. MoonFibre will be used for landing pads and roads preventing dust plumes.

Left: Rock falling on Lunar dust | Right: Rock falling on MoonFibre pad.

Videos by Frank Koch

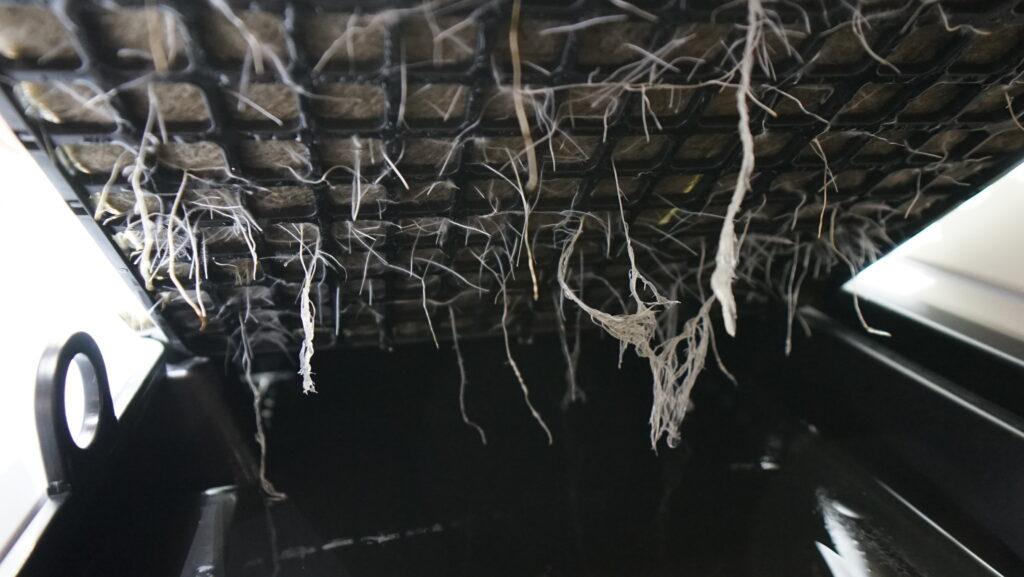

Hydroponic growth substrate

MoonFibre pads provide a substrate that efficiently distributes water and nutrients, making hydroponic plant growth highly effective. MoonFibre enables reliable food production and life-support experiments under Lunar conditions.

Images by DLR (German Aerospace Center)

We have tested multiple Lunar regolith simulant types and produce simulant fibres for research and development, including Moon base construction studies. Specific combinations are produced on request to simulate landing zones and evaluate expected mechanical properties.

We have tested multiple Lunar regolith simulant types and produce simulant fibres for research and development, including Moon base construction studies. Specific combinations are produced on request to simulate landing zones and evaluate expected mechanical properties.

We have tested multiple Lunar regolith simulant types and produce simulant fibres for research and development, including Moon base construction studies. Specific combinations are produced on request to simulate landing zones and evaluate expected mechanical properties.