At Fibrecoat, we are thrilled to announce the continuation of our dynamic partnership with Saint-Gobain, a global leader in the design, production, and distribution of materials and solutions. Formerly an investor, Saint-Gobain has now joined us as a commercial partner, marking a significant milestone in our journey towards revolutionizing the materials industry.

Our collaboration is built on a shared commitment to innovation, sustainability, and excellence. As a pioneer in advanced materials, Saint-Gobain brings a wealth of experience and a robust global network to our partnership. This synergy enhances our ability to deliver cutting-edge, sustainable solutions that meet the evolving needs of our customers.

Our transition from an investor relationship to a commercial partnership signifies a strategic move to drive growth and expand our market reach. With Saint-Gobain’s support, we are better equipped to penetrate new markets and deliver innovative solutions to a broader audience.

As we move forward, Fibrecoat and Saint-Gobain are united in our pursuit of success. We are confident that this partnership will yield groundbreaking advancements and set new standards in the materials industry. Together, we are not just imagining the future; we are creating it.

Stay tuned for more updates as we embark on this exciting new chapter , transforming the possibilities of fibre coating technology!

As our team continues to grow and our local production expands, we’re relocating to a new, larger space. After countless memories made and much achieved at Dennewartstraße, it was time for a change. This move marks a significant milestone in our journey towards making the future affordable.

As we bid farewell to our old address, we eagerly anticipate the huge opportunities and growth awaiting us in our new home. Join us as we transition to a space where innovation thrives and possibilities are limitless.Eager to experience our new headquarters? Get in contact with us, so we can schedule a meeting! Whether you’re a long-time supporter or a curious newcomer, we can’t wait to share our vision with you and explore what lies ahead. Here’s to new beginnings and exciting adventures ahead. See you at Lumileds!

FibreCoat GmbH

Philipsstr.8

52068 Aachen

Germany

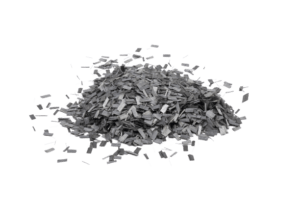

Our aluminium-coated chopped strands are ready for shipment. Developed as a filler for electrical and thermal conductive engineering compounds.

Reach out to our team to learn more and order your samples to lead the way to the future of composites.

This year, the JEC Composites Startup Booster competition will celebrate its 5th anniversary with a special event on-site and the launch of a brand new award dedicated to sustainability.

As a winner of the startup prize at the JEC DACH Forum FibreCoat automatically moved to top 20 finalist and will pitch their project in front of a global audience during the JEC in Paris.

Five investors fund Series A round to increase capacity, increase sales and marketing activities

(Aachen) 17.11.2021—FibreCoat GmbH, an innovative composite materials spin-off from the Institut für Textiltechnik (ITA) of RWTH Aachen University, announces it closed a $3 million Series A round with Goose Capital, Phoenix Venture Partners, b.value AG, NOVA by Saint-Gobain and the TiE Houston Angels, led by Ashok Rao (Goose Capital). The capital raised is being used to expand the FibreCoat team to increase sales and marketing activities as the company looks to increase capacity and to allow FibreCoat to build new partnerships in the construction, electronics, and automotive industry.

“These strong investors offer a knowledgeable background in materials and a diverse network into the markets we serve as we lay the foundation for scaling our technology to increase our capacity from 10 tons per month by the end of 2021 to 60 tons per month in 2022,” said Robert Brüll, CEO, FibreCoat.

FibreCoat offers a revolutionary coating technology for fibres in composite and shielding applications as a basic building block for tomorrow’s mobility and construction industries. Developed by co-founders Robert Brüll, Alexander Lüking, and Richard Haas as part of their doctoral studies at the RWTH Aachen University (Germany), FibreCoat’s product lines include AluCoat, metal-coated basalt fibres used for electromagnetic shielding and conducting applications, and PolyCoat, thermoplastic-coated glass fibres used for strengthening and light weighting applications. The coated fibres provide substantial quality advantages due to the single-filament coating and the tunability of the materials (e.g., adjustable coating thickness, homogeneity, thin core fibres).

FibreCoat produces application- and customer-specific bicomponent filaments for a wide range of applications resulting in disruptive advances in the composite and EMI shielding industries. It provides a significant advantage over other technologies due to its high speed and one-step technology process, with substantial-quality advantages resulting from the single-fibre coating. The high-performance fibres not only improve existing products but enable completely new mass market applications in areas ranging from light-weight EMI shielding in electric vehicles and defence applications to drape-able EMI shielding fabrics for smart textiles or wallpapers in hospitals.

“In addition to high-coating flexibility, our extensive network for customer-specific processing of coated fibres differentiates us from our competitors,” said Brüll. “Our first market-ready product, AluCoat, saves up to 90 percent in CO2 emissions during production when compared to alternative materials, such as solid metal fibres, and aluminium foils and sheets, while also being fully recyclable.”

The Series A funding was a result of FibreCoat’s outstanding technology and performance at this year’s Rice Business Plan Competition (RBPC), where the company was represented as the TiE Global automatic European entry after successfully winning TiE Global’s feeder competition in Europe. As the largest intercollegiate start-up competition in the world, RBPC provided the perfect combination with TiE for FibreCoat to leverage an extensive network, placing third in the final competition.

The RBPC invites start-ups from 42 top universities from around the world to compete at the Jones Graduate School of Business at Rice University each spring in front of over 300 investors and other judges for over $1.5 million in prize money. Past RBPC alumni have raised more than $3.5 billion in funding. “This achievement attracted the attention of Goose Capital, which led to the success of this round,” added Brüll.

Goose Capital began 15 years ago as a small group of successful executives committed to supporting emerging entrepreneurs and has evolved into a professional investment organization providing capital, mentorship, and board members to early-stage companies. Members of Goose Capital have broad experience across multiple industry sectors. Goose Capital has invested over $50 million in start-ups, and currently has around twenty companies in its portfolio.

Goose Capital provides the Grand Prize at the Rice Business Plan Competition and often provides much more, having invested over $20 million in RBPC winners alone. “We are thrilled to be part of this incredible competition, delivering high quality teams to Rice, from Universities in Europe and Asia”, said Ashok Rao, past Chairman of TiE Global and the founder of this feeder competition program along with Brad Burke, Managing Director of the Rice Alliance. “Our teams from Europe and Asia have acquitted themselves admirably for the 10 years this program has been in existence with 4 teams having made it the finals while obtaining over $10 million in investment from Goose.” And in his role of Board Director of Goose Capital and future Chairman of the Board of Directors of FibreCoat, Rao added “FibreCoat is an exciting investment opportunity for our Goose members. The interest level was so high that this offering was oversubscribed by 200%.”

The b.value team has more than 40 years of experience in setting up, leading, and developing technology companies and commercializing biotechnological developments. Their investment philosophy focuses on talented entrepreneurs who want to create a passionate company with knowledge and courage from a business model with high scalability and disruptive proprietary technology. “We are very proud to welcome FibreCoat with their ground-breaking composite fibres to our portfolio. We believe that FibreCoat will revolutionize the composites market in the coming years, and b.value AG is delighted to be part of this journey,” said Georg Lentzen, Managing Director, b.value

Phoenix Venture Partners (PVP) invests at the convergence of advanced materials, biology and hardware with advanced computation and AI. PVP employs a multi-stage investment strategy, encompassing both seed and venture investment programs, and assists entrepreneurs with customer and supply chain business development.

NOVA by Saint-Gobain, the corporate venturing arm of Saint-Gobain, acts as a bridge by working with qualified start-ups by providing access to Saint-Gobain’s internal resources and helping start-ups form long-term partnerships. Rooted in trust, expertise, support, and flexibility, the NOVA team supports entrepreneurs whose focus aligns with their expertise to create a path to market. “Our partnership with FibreCoat will bring innovative solutions to our customers and aligns well with our mission of making the world the better home,” said Minas Apelian, Vice President, Internal and External Venturing, Saint-Gobain.

The mission of the TiE Houston Angels is to foster entrepreneurship through mentoring, networking, education, funding, and incubation. With a focus on giving back to the community, TiE’s focus is on generating and nurturing the next generation of entrepreneurs. The overall aim is to empower individuals and create wealth in communities by assisting entrepreneurs.

FibreCoat is interested to connect with anyone interested in affordable conductive fibres and would like to reach out to info@fibrecoat.de or visit www.fibrecoat.de.

FibreCoat is delighted to invite you to visit us on 13th MetalMadrid Trade Fair 2021, a leading annual industrial show tailored to meet the needs of today’s advanced manufacturers and suppliers. We are inviting you to stop by and find out more about our EMI shielding composite fibres.

The 13th MetalMadrid Trade Fair 2021 is the most important specialized event in this branch in Spain. It is to be held from November 17 and 18, 2021 at IFEMA, Madrid, gathering the leading companies from all branches of the metal industry. This year, it is expected to cover more than 15,000 m2. of exhibition space with more than 600 exhibitors from 30 countries and more than 20,000 visitors.

This year Metal Madrid is joined by Composites Madrid, the only fair in Spain dedicated to composite and advanced materials, and Robomática, the leading fair in industrial automation and robotics. Along with them, a multitude of sectors necessary for our industry; connected industry, additive manufacturing, surface treatment, sheet metal and aluminum processing, multi-sector components, supplies, and much more.

Don’t miss this opportunity to meet us face to face. See you there!

Together with our partner DBF, Fibrecoat has won first place at the IQ Innovationspreis Mitteldeutschland. Taking home another award thanks to the continuous effort of our team and partners.

With the cluster innovation competition IQ Innovationspreis Mitteldeutschland, the European metropolitan region of Central Germany promotes new, marketable products, processes and services to increase innovation and competitiveness in Central Germany. The nationwide competition is organized in five industry-specific clusters.

For more information you can visit IQ-Innovationspreis Mitteldeutschland.