At Fibrecoat, we are thrilled to announce the continuation of our dynamic partnership with Saint-Gobain, a global leader in the design, production, and distribution of materials and solutions. Formerly an investor, Saint-Gobain has now joined us as a commercial partner, marking a significant milestone in our journey towards revolutionizing the materials industry.

Our collaboration is built on a shared commitment to innovation, sustainability, and excellence. As a pioneer in advanced materials, Saint-Gobain brings a wealth of experience and a robust global network to our partnership. This synergy enhances our ability to deliver cutting-edge, sustainable solutions that meet the evolving needs of our customers.

Our transition from an investor relationship to a commercial partnership signifies a strategic move to drive growth and expand our market reach. With Saint-Gobain’s support, we are better equipped to penetrate new markets and deliver innovative solutions to a broader audience.

As we move forward, Fibrecoat and Saint-Gobain are united in our pursuit of success. We are confident that this partnership will yield groundbreaking advancements and set new standards in the materials industry. Together, we are not just imagining the future; we are creating it.

Stay tuned for more updates as we embark on this exciting new chapter , transforming the possibilities of fibre coating technology!

As our team continues to grow and our local production expands, we’re relocating to a new, larger space. After countless memories made and much achieved at Dennewartstraße, it was time for a change. This move marks a significant milestone in our journey towards making the future affordable.

As we bid farewell to our old address, we eagerly anticipate the huge opportunities and growth awaiting us in our new home. Join us as we transition to a space where innovation thrives and possibilities are limitless.Eager to experience our new headquarters? Get in contact with us, so we can schedule a meeting! Whether you’re a long-time supporter or a curious newcomer, we can’t wait to share our vision with you and explore what lies ahead. Here’s to new beginnings and exciting adventures ahead. See you at Lumileds!

FibreCoat GmbH

Philipsstr.8

52068 Aachen

Germany

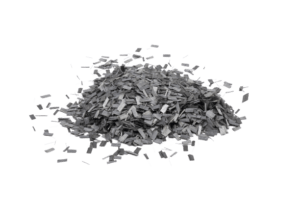

Our aluminium-coated chopped strands are ready for shipment. Developed as a filler for electrical and thermal conductive engineering compounds.

Reach out to our team to learn more and order your samples to lead the way to the future of composites.

This year, the JEC Composites Startup Booster competition will celebrate its 5th anniversary with a special event on-site and the launch of a brand new award dedicated to sustainability.

As a winner of the startup prize at the JEC DACH Forum FibreCoat automatically moved to top 20 finalist and will pitch their project in front of a global audience during the JEC in Paris.