Discover our advanced coated fibres, engineered for high-performance applications across defence, space, automotive, and more. We offer two primary product families, each tailored for demanding environments:

Metal-coated fibres

We specialise in high-performance metal-coated fibres (with glass or basalt core) that combine strength, electrical conductivity, and thermal regulation.

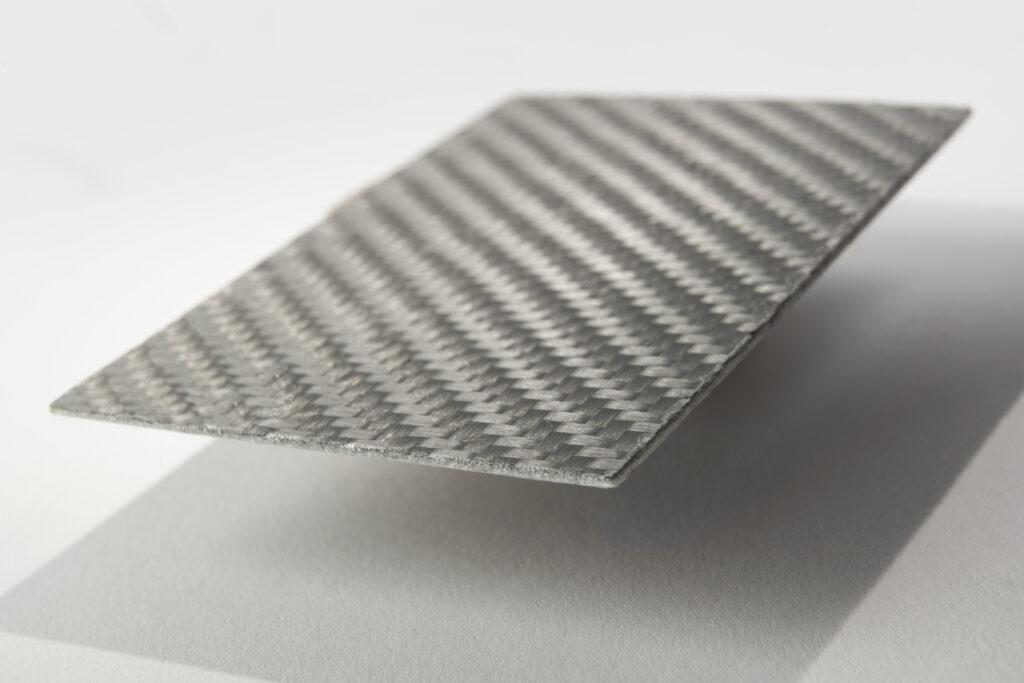

ALUCOAT

ALUCOAT is our revolutionary flagship material, with applications in defence, space, automotive and a wide range of other industries. Blending the strength of basalt/glass with the conductivity of aluminium, ALUCOAT’s ultra-light, high-performance fibres guarantee resilience and connectivity on earth or in space – at a fraction of the usual cost. Available formats:

We develop customised products for other material combinations as well.

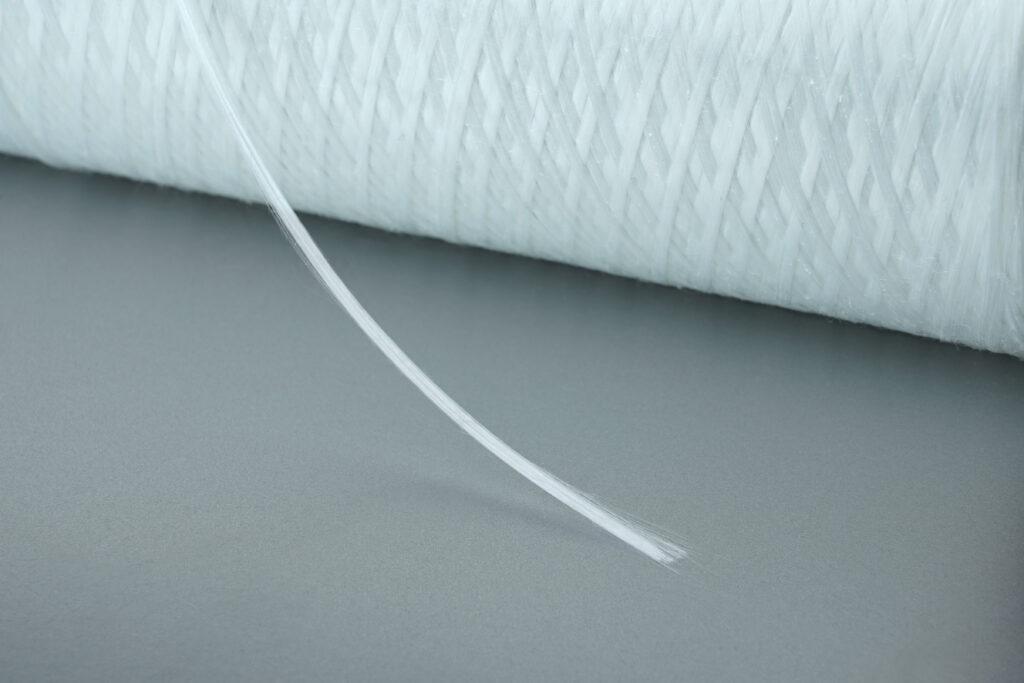

Yarn

Electrical resistance <12 Ω/m at 50 tex ℹ️

| Tex | Resistance (Ω/m) |

|---|---|

| 50 | < 12 |

| 100 | < 8 |

| 200 | < 6 |

| 600 | < 3 |

| 1200 | < 1 |

| 2400 | < 1 |

| Tex | Resistance (Ω/m) |

|---|---|

| 50 | < 12 |

| 100 | < 8 |

| 200 | < 6 |

| 600 | < 3 |

| 1200 | < 1 |

| 2400 | < 1 |

- 50-2400 tex

- Maximum working temperature up to 400 °C

- Tensile strength of 1,5GPa

- Elastic modulus of 70 GPa

- Custom sizing

Chopped

- Compounding

- Chaff

- Molding

- Filling

- Bulk density 0,345 g/cm³

- Pourable

- Custom filament length

Sn

Tin coated fibre

Corrosion-resistant fibre designed for durability.

Zn

Zinc coated fibre

Robust fibre ideal for long-lasting industrial applications.

Bi

Bismuth coated fibre

Fibre designed for radiation shielding.

Ni

Nickel coated fibre

Corrosion-resistant fibre designed for durability.

Cu

Copper coated fibre

Corrosion-resistant fibre designed for durability.

Cu + Zn

Brass coated fibre

Corrosion-resistant fibre designed for durability.

Sn

Tin coated fibre

Corrosion-resistant fibre designed for durability.

Zn

Zinc coated fibre

Robust fibre ideal for long-lasting industrial applications.

Bi

Bismuth coated fibre

Fibre designed for radiation shielding.

Ni

Nickel coated fibre

Corrosion-resistant fibre designed for durability.

Cu

Copper coated fibre

Corrosion-resistant fibre designed for durability.

Cu + Zn

Brass coated fibre

Corrosion-resistant fibre designed for durability.

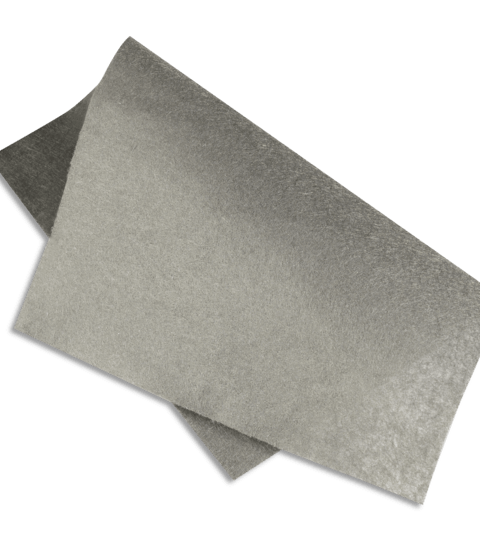

Polymer-coated fibres

Our polymer-coated fibres deliver targeted performance and robust protection in demanding environments. Engineered to enhance durability, minimise abrasion, and meet specific chemical and thermal needs, these fibres offer reliable solutions where resilience and precision matter most.

PolyCoat

- Textile character 50-1500 tex

- E-glass core with thermoplastic polymer coating

- 5-20% volume fraction of polymer

R&D Services

We offer a comprehensive range of R&D services, from feasibility studies to market-ready products. Our capabilities include fibre development, coating technologies, material optimisation, application engineering for seamless integration into customer processes, specialised pilot lines, and advanced analytical tools.

Analytical services

- Optical and scanning electron microscopy (SEM)

-

Mechanical testing with universal testing machines (load cells: 5N, 500N and 2500N)

● DIN EN ISO 5079:2021-02 Textiles - Fibres - Determination of breaking force and elongation at break of individual fibres - Loss-on-ignition testing to determine sizing/organic content on fibre/yarn

-

Electromagnetic properties analysis:

● ASTM D4935 Standard test method for measuring the electromagnetic shielding effectiveness of planar materials in the frequency range of 100 kHz - 1.5 GHz

● Complex permeability and permittivity properties using X-Band WR90 Wave guide setup

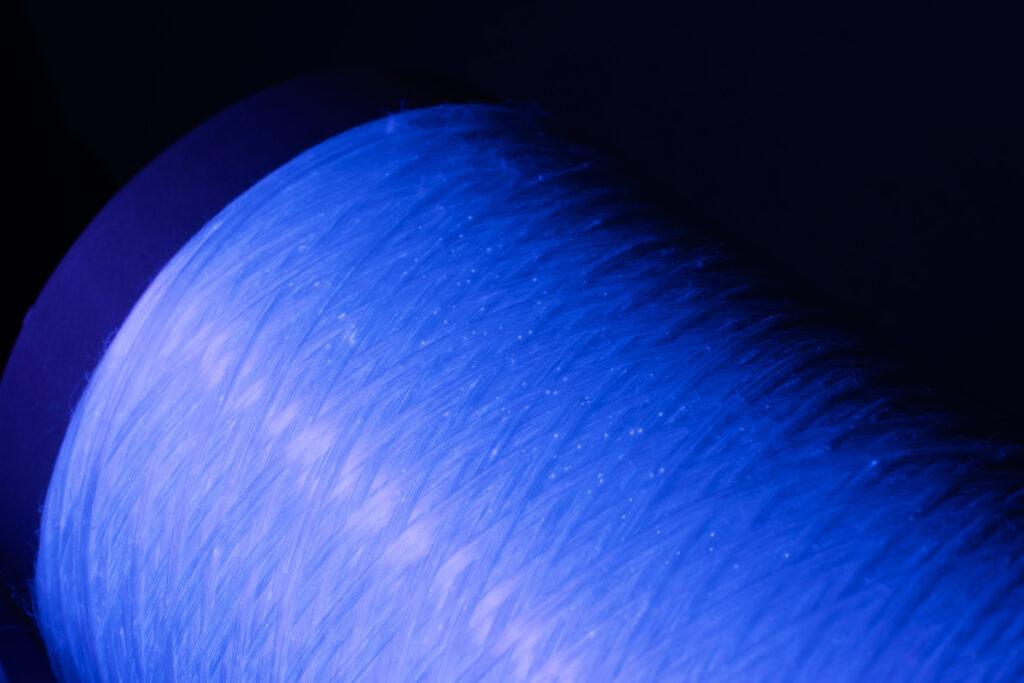

Pilot & lab facilities

- Glass fibre spinning lines (lab (1 & 5 nozzels), Metalcoat line (50 nozzels) and semi-commercial (800 nozzles with scalable capacity)

- Industrial Dietze + Schell spinncake winders with speeds from 100 m/min up to 4000 m/min on all spinning lines including the lab line

- Induction heating and remelt technology for metal/polymer coatings

- Modular pilot equipment for customised trials under real process conditions

Process, product and equipment development

- In-line coating development on glass fibres: metals and polymers

- Off-line coating development of other fibre types with metals and polymers

- Development of sizing/spin finish formulations for glass fibre and other fibre types

- Feasibility studies, prototypes, and process scaling

- Fluid dynamics simulation of high-speed coating process

Product development & application engineering

- Adaptation and customization of our materials and products for integration into customer processes

- Testing fibre properties to meet customer demands (mechanical, thermal, electrical, etc.)

- Product optimisation for process efficiency, product performance, and cost-efficiency

Process, product and equipment development

- In-line coating development on glass fibres: metals and polymers

- Off-line coating development of other fibre types with metals and polymers

- Development of sizing/spin finish formulations for glass fibre and other fibre types

- Feasibility studies, prototypes, and process scaling

- Fluid dynamics simulation of high-speed coating process

Product development & application engineering

- Adaptation and customization of our materials and products for integration into customer processes

- Testing fibre properties to meet customer demands (mechanical, thermal, electrical, etc.)

- Product optimisation for process efficiency, product performance, and cost-efficiency

Our team brings together core competencies in mechanical engineering, textiles, chemistry, polymers, metallurgy, and electromagnetics, with dedicated engineers and lab technicians focused on testing and prototyping.

Our team brings together core competencies in mechanical engineering, textiles, chemistry, polymers, metallurgy, and electromagnetics, with dedicated engineers and lab technicians focused on testing and prototyping.